Supply chain is such a vast subject, encompassing so many different concepts that it’s easy to get lost. For people who aren’t immersed in it on a daily basis, the notion of what a supply chain is can quickly become abstract.

Let’s simplify things for you in the following article!

Article by Annick Beauparlant.

Supply chain

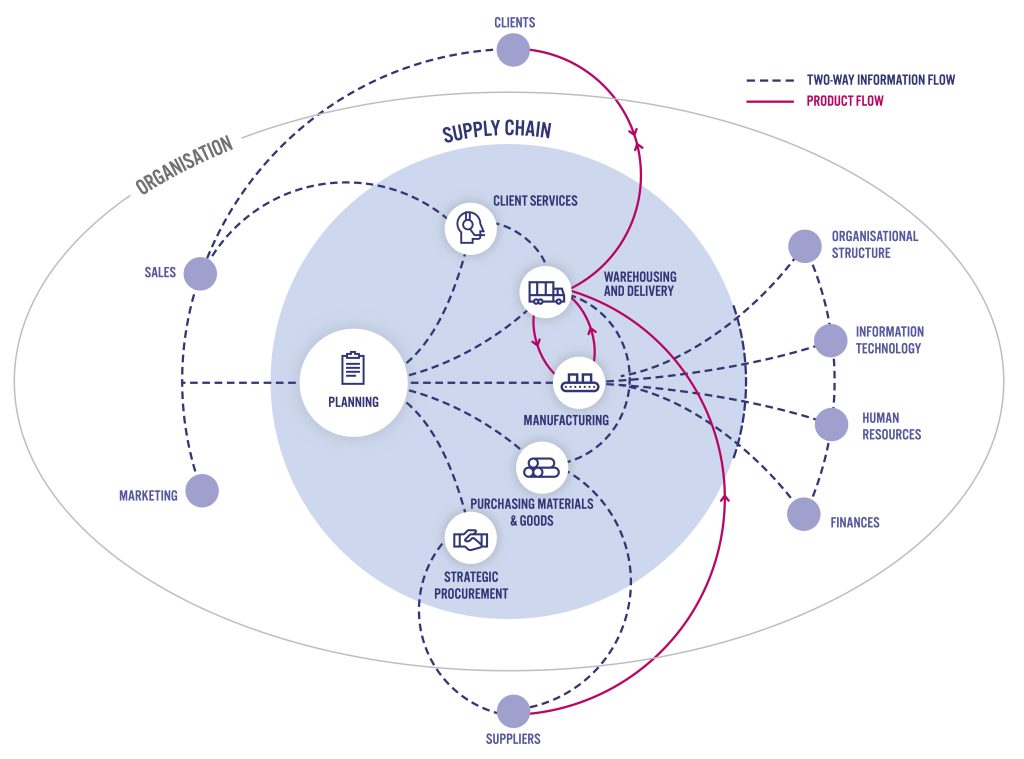

The supply chain is the set of activities required to bring a product or service to its final consumer. The main activities are strategic sourcing, raw materials purchasing, manufacturing (or processing, as the case may be), warehousing and delivery, and customer service.

The diagram below provides a clear graphic representation.

Supply Chain Planning

At The Heart of The Organization

Planning is the first strategic step. Proper and accurate planning will enable a company to better coordinate all subsequent supply chain activities. Let’s not forget a basic business principle: offer your customer the right product, at the right time, at the right price. A well-functioning, efficient supply chain makes this possible. Sales and marketing teams provide the guidelines for supply chain activities. This is commonly known as “Sales and operation planning (S&OP)”. Attention: a strategic alignment of sales and marketing with the supply chain is essential. This alignment will help create synergy and benefit from more effective planning, ensuring that the customer’s promise is kept.

Essential To The Supply Chain

Supply chain business planning refers to short-term requirements to achieve our objectives, such as sales forecasts for different distribution channels. It can also encompass medium/long-term needs to align with the company’s strategic vision. For example, we want to make sure we plan the launch of a new product line, both in terms of marketing by the sales and marketing teams, and in terms of the supply chain. You’ll want to identify which strategic suppliers will be involved, whether there will be any quality tests to be carried out on the new raw materials to be purchased, and validate whether current warehousing capacity is sufficient to support such a launch. With proper planning, a company can be sure of being able to support its growth, however rapid.

Supply Chain Stakeholders

The Importance Of Supplier Relations

Strategic sourcing and purchasing of raw materials and products are directly linked to a company’s external suppliers. More and more emphasis is being placed today on the importance of these supplier relationships. Indeed, close collaboration with certain of a company’s strategic suppliers can generate numerous benefits that will impact the rest of the supply chain. With access to data now facilitated by technology, sharing strategic information with suppliers can enable a company to considerably reduce its response time to variations in demand. Different inventory management strategies can be put in place to save time and reduce lead times on specific components.

Of course, such close ties and proximity also increase a company’s risk and codependence on its supplier, so it’s very important to choose carefully with whom to develop these privileged relationships.

Conversely, it can be just as important to diversify suppliers on strategic components in order to minimize risk. The pandemic was a painful test for many in this respect. When a company relies entirely on a single strategic supplier, a major event on the scale of what we experienced with COVID-19, for example, can put a company’s very survival at risk.

Manufacturing, production or transformation refer to the company’s core business. In other words, it’s what sustains the company, its raison d’être. This is where the greatest added value for the consumer is to be found.

The Importance of Knowing Your Customers

For some years now, and increasingly so, customer data has been a veritable goldmine for managers. Using relevant data and targeted customer information to improve sales forecasts, better anticipate market variations and help plan more accurately are all strategies that put artificial intelligence at the service of the supply chain.

Finally, organizational structure, information technology, human resources and finance will support all stages of the supply chain. Here again, strategic alignment is essential, to ensure that everyone is working in the same direction, towards a common goal.

Supply chain optimization

The supply chain is made up of a number of so-called non-value-added activities, i.e. those necessary to deliver the product or service to the consumer, but for which the consumer does not associate any additional value. There are therefore many concepts aimed at optimizing supply chain activities. This is where a company can stand out from the crowd and remain financially competitive.

Inventory management, continuous improvement and quality management are just a few examples. In fact, the customer experience begins with distribution operations, and any improvements must take this into account.

Typically, we’ll find many optimization initiatives in warehousing and product delivery activities. Distribution centers and transportation are major cost centers for most companies. But process optimization concepts apply to all areas of an organization. Integrating optimization initiatives into an organization’s day-to-day operations helps to build a resilient corporate culture and higher-performing teams in which adaptability is a real competitive advantage.

In conclusion, although the supply chain is a vast and complex subject, it lies at the heart of every business and deserves special attention. Many competitive advantages can be derived from it!

At Aristeío, we help our customers optimize their processes, from physical warehousing and distribution operations to employee hiring and training, and business development, to name but a few recent examples.

Contact us to find out more!

Don’t miss out on our next articles, subscribe to our newsletter!