What if a 5S organisation training could improve the daily life of your teams?

Information loss, poor time management, messy workshops, disorganised warehouses … are factors that slow down your performance, cause frustration among your employees and affect your customers?

Then we have the solution for you: the 5S Organisation training.

Some 50 years ago, Toyota understood this. They created the 5S organisation method and implemented it in all their production lines. With a vision towards continuous improvement, they developed a solution to increase performance on the shop floor while respecting employee safety.

5S Method

This visual 5S management approach makes it easy to identify where tools, parts, components, etc. are located. It allows to:

- reduce time wastage

- improve employee health and safety

- reduce hygiene and sanitation problems

- practice team discipline by setting and maintaining work standards.

To read more on this subject, see our article on 5S

5s Training

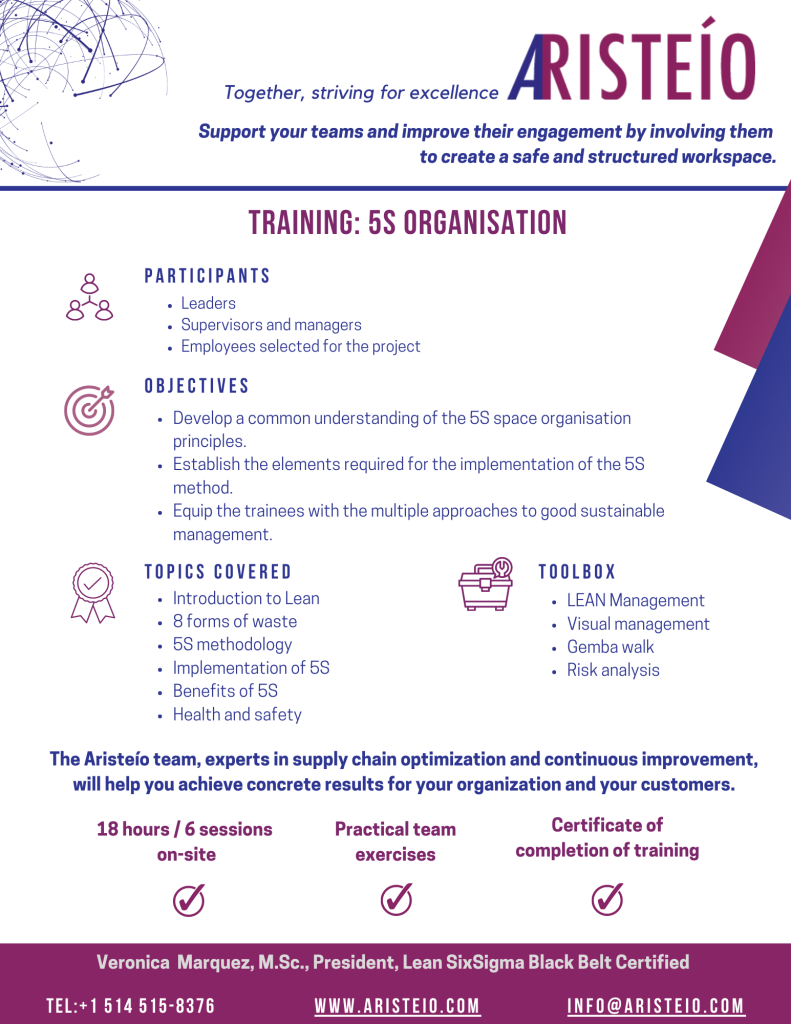

Arsiteío has developed a training course to equip your teams with tools that will allow them to apply the 5S method in their daily work and to optimize your supply chain. And all this from a continuous improvement perspective!

This 18-hour training course, offered in person, will also cover Lean Management techniques, with a section on health and safety. Your teams will be able to put their knowledge into practice through concrete exercises: a way to better master their new skills.

Ready to take the step to improve the daily life of your teams, stimulate team spirit and improve the performance of all?

CONTACT US TO FIND OUT MORE!