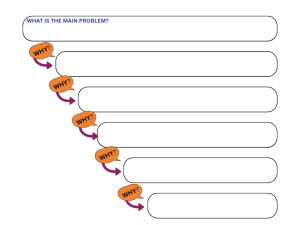

Why We Keep Fixing Symptoms Instead of Causes

Every organization faces recurring issues: a machine keeps breaking down, delivery delays repeat, the same client complaint resurfaces. Too often, we patch the symptom instead of addressing the source.

The 5 Whys technique invites us to pause and dig deeper. By repeatedly asking “why?” until the root cause emerges, teams move from firefighting to prevention—an essential shift for sustainable performance and resilience.

What Is the 5 Whys Technique?

The 5 Whys method was developed by Sakichi Toyoda in the early days of the Toyota Production System. His philosophy was simple: if you want to understand a problem, keep asking “why?” until you reach the process or behaviour that truly caused it.

“By repeating why five times, the nature of the problem as well as its solution becomes clear.” — Taiichi Ohno, Toyota.

The power of this approach lies in its simplicity. You don’t need software or statistics—just curiosity, teamwork, and honesty.

Example

-

The machine stopped.

-

Why? Because it overloaded.

-

Why? Because the bearing wasn’t lubricated.

-

Why? Because the maintenance schedule was missed.

-

Why? Because no one was assigned to it.

-

Why? Because roles weren’t clearly defined.

The root cause isn’t mechanical—it’s managerial. Fix the process, and you fix the problem.

How to Apply the 5 Whys in Practice

-

Define the problem clearly. Describe the issue in measurable terms—what happened, where, and how often.

-

Gather the right people. Include those who see the problem daily; they often hold critical insights.

-

Ask “why?” repeatedly. Each answer becomes the next “why” until you reach a process or system cause, not a person.

-

Verify each cause with data or observation. Evidence prevents jumping to conclusions.

-

Identify countermeasures and assign ownership. The goal isn’t blame—it’s learning and prevention.

Transition phrases such as first, then, next, finally help keep the conversation structured and focused.

5 Whys and the Ishikawa Diagram: Two Tools, One Purpose

While the 5 Whys helps you follow a single chain of reasoning, the Ishikawa diagram (or fishbone diagram) helps visualize multiple potential causes at once.

-

Use the fishbone diagram when a problem has many possible factors—people, methods, machines, materials, environment, or measurement.

-

Use the 5 Whys when one branch or cause needs deeper exploration.

Together, they create a powerful one-two punch for root cause analysis: start broad with the fishbone to brainstorm causes, then narrow with the 5 Whys to uncover the real driver.

Learn more in our related article: The Fishbone Diagram.

Avoiding Common Pitfalls

The 5 Whys seems simple, but misuse can lead to frustration or shallow results.

-

Stopping too early. Many teams stop at the first “human error.” Keep digging until you find the process gap.

-

Looking for someone to blame. The goal is understanding, not fault-finding.

-

Neglecting verification. Each answer must be validated by data or observation, not assumptions.

-

Working alone. The 5 Whys works best as a team exercise—diverse perspectives reduce bias.

When done correctly, it strengthens trust and problem-solving capability across the organization.

The 5 Whys Meets AI: Smarter Root Cause Analysis

Today, AI tools can help accelerate the analysis phase without replacing human reasoning.

-

Process-mining software like Celonis automatically detects patterns in data logs, revealing where delays or errors start.

-

Anomaly-detection algorithms flag irregularities in cycle time or quality metrics, guiding teams toward the most likely cause.

-

Natural-language processing (NLP) tools can scan maintenance notes or customer feedback to group common issues before the first “why” is even asked.

For example, a study from BCG (2024) shows that companies integrating AI with Lean achieve 20–30 % faster improvement cycles because teams spend less time collecting data and more time solving problems (source).

Still, AI’s role is supportive. It can point to correlations or patterns, but only people can confirm causation. As one Toyota engineer put it, “Machines show us what’s happening. People explain why.”

Why It Still Starts with People

Even the most advanced analytics need human context. The 5 Whys remains relevant because it teaches disciplined curiosity—an essential mindset for continuous improvement.

When teams can ask “why” safely and openly, they build psychological safety and shared ownership. Over time, this mindset strengthens operational resilience: issues are detected earlier, lessons are shared faster, and continuous improvement becomes part of daily work.

Take-Away

The 5 Whys isn’t just a tool—it’s a conversation about how we think, learn, and improve together. By combining it with visual tools like the fishbone diagram and AI-driven insights, organizations can uncover causes faster, fix them sustainably, and empower teams to own their processes.

Every improvement begins with a question. Whether you’re tackling quality issues, customer complaints, or process inefficiencies, start by asking “why.”

At Aristeio, we help organizations build problem-solving cultures where teams own their processes and use practical tools—from the 5 Whys to AI-enhanced analytics—to achieve sustainable performance.

Explore more tools and insights on our blog or contact us to learn how we can help your team uncover root causes and drive operational excellence.

FAQ

What is the 5 Whys technique?

It’s a simple problem-solving method that asks “why” repeatedly (about five times) to uncover the root cause of an issue rather than treating symptoms.

How does the 5 Whys relate to the fishbone diagram?

The fishbone diagram maps multiple potential causes, while the 5 Whys explores one cause in depth. Used together, they create a complete root-cause analysis.

Can AI help with root-cause analysis?

Yes. AI can analyze data patterns, highlight anomalies, and group issues faster, but human teams still interpret the results and confirm real causes.

Why is asking “why” five times effective?

Repeating “why” reveals process weaknesses hidden beneath surface symptoms, helping organizations prevent recurrence and foster continuous improvement.

Additional Reading:

Ohno, T. (1988) Toyota Production System: Beyond Large-Scale Production. CRC Press. Boca Raton, FL.

About Veronica B. Marquez, M.Sc, CSSBB

I help growing manufacturing and service organizations scale without chaos—by turning operational challenges into sustainable performance gains. My superpower is making strategy real at every level of the business: connecting people, processes, and purpose to drive productivity, engagement, and resilience. I bring clarity to complexity and help teams execute better, faster, together. Through a proven lens of operational excellence, continuous improvement, and supply chain optimization, I work with leaders to align efforts, simplify execution, and create systems that actually support growth.

I help growing manufacturing and service organizations scale without chaos—by turning operational challenges into sustainable performance gains. My superpower is making strategy real at every level of the business: connecting people, processes, and purpose to drive productivity, engagement, and resilience. I bring clarity to complexity and help teams execute better, faster, together. Through a proven lens of operational excellence, continuous improvement, and supply chain optimization, I work with leaders to align efforts, simplify execution, and create systems that actually support growth.

Named one of the Top 50 Experts in Operational Excellence by the PEX Network and ranked in the Favikon Top 200 Global Creators in Risk & Resilience (#13 worldwide, #3 in Canada), I bring over 20 years of experience across sectors like manufacturing, distribution, mining, and public services. I teach Lean Six Sigma at the executive education level, lecture on service design in a master’s program, and host a LinkedIn Live series focused on Excellence in Industry 5.0. Ready to explore how operational excellence can transform your business? Reach out https://www.linkedin.com/in/veronicabm/.

📷 Canva